SEPAR FILTERS: DIESEL FUEL CLEANLINESS

These Days, It's All About Fuel Care

In today's agricultural and industrial sectors, diesel engines are the lifeblood of operations. Whether you're powering a combine harvester in the fields of Alberta or running heavy machinery on a construction site in Saskatchewan, the performance of your diesel engine is critical. But performance isn't just about the engine itself—it's also about the fuel quality you're using. With the increasing complexity of modern diesel engines, fuel care has become more crucial than ever.

The Importance of Fuel Cleanliness: ISO Standards

Fuel cleanliness is not just a matter of preference; it's a requirement. The International Organization for Standardization (ISO) has established standards for fuel cleanliness that are widely recognized across industries. The ISO 4406 standard, for instance, is used to quantify the cleanliness of fuels by counting and categorizing the number of particles present in the fluid.

The importance of adhering to these standards cannot be overstated. Dirty fuel can lead to premature wear of engine components, reduced efficiency, and costly downtime. As engines become more advanced, with tighter tolerances and higher pressures, the smallest contaminants can cause significant damage.

Proper Filtration: The First Line of Defense

To meet the new and stringent cleanliness standards, proper filtration is essential. Filtration systems are designed to remove contaminants such as dirt, water, and other particulates that can wreak havoc on a diesel engine. A high-quality filtration system ensures that the fuel entering your engine is as clean as possible, protecting sensitive components like fuel injectors and pumps from damage.

SEPAR Fuel Filtration: The Gold Standard

Regarding fuel filtration, SEPAR stands out as a leader in the industry. SEPAR filtration systems are designed to provide the highest level of protection for diesel engines. They are particularly effective in removing water from fuel—a critical function since water is one of diesel fuel's most common and damaging contaminants.

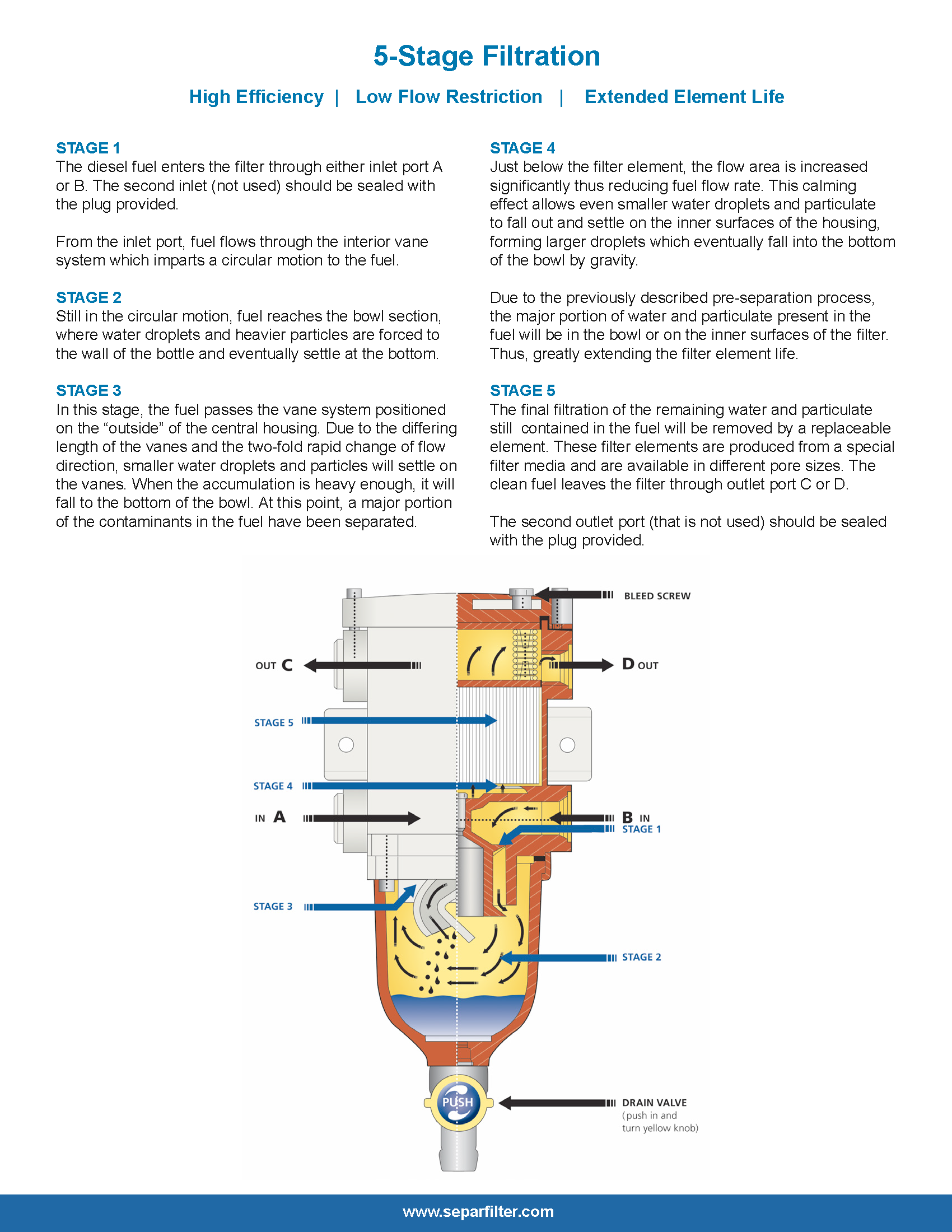

SEPAR's unique multi-stage filtration process sets it apart from other systems. It removes large particles and filters out fine particulates and emulsified water, ensuring that your engine is fed with the cleanest possible fuel. This level of filtration is essential in preventing damage and maintaining the efficiency of modern diesel engines.

Check out the 5-step process detailed by SEPAR below:

Fuel Contamination Starts from Within: The Role of Injector Deposits

One of the lesser-known facts about fuel contamination is that it doesn't always come from external sources. Fuel contamination can start inside the engine, particularly by forming Internal Diesel Injector Deposits (IDID). These deposits form in the injector nozzles, leading to poor fuel atomization, stickiness, reduced combustion efficiency, and engine performance issues.

IDID is a growing concern, especially with the advent of ultra-low sulphur diesel (ULSD) fuels, which tend to have lower lubricity and can contribute to deposit formation. Once these deposits form, they can be difficult to remove, leading to costly repairs if not addressed promptly.

Fighting Fuel Contamination with 4+ Super Clean

To protect against fuel contamination and keep your engine running smoothly, we recommend using 4+ Super Clean. This advanced fuel additive is specifically designed to combat the formation of IDID and other harmful deposits. 4+ Super Clean cleans the fuel system, breaks down existing deposits, and prevents new ones from forming.

Regular use of 4+ Super Clean not only helps maintain your fuel's cleanliness but also enhances fuel stability and improves engine performance. It's a simple, cost-effective way to ensure your diesel engine runs at its best, no matter the conditions.

Conclusion: Invest in Fuel Care for Long-Term Performance

In the world of diesel engines, fuel care is no longer optional—it's a necessity. By adhering to ISO standards for fuel cleanliness, investing in top-tier filtration systems like SEPAR, and using products like 4+ Super Clean, you can protect your engine from the damaging effects of fuel contamination. The result is a more reliable and efficient engine and a longer lifespan for your equipment.

These days, it's all about fuel care, and the right choices today can save you time, money, and headaches tomorrow.

CLICK HERE TO LEARN MORE ABOUT SEPAR FILTERS AND THE IMPORTANCE OF MAINTAINING YOUR FUEL QUALITY.

Water and Particulate Build-Up

In addition to causing engine malfunctions, water in fuel can also allow the formation of bacterial growth.

Left unchecked, this can result in clogged filters and injectors, leading to sudden engine failure. This makes eliminating water and particulates from fuel critically important.